ADASH Lubri 4910 – Smart Greasing and Vibration Monitoring in One Tool

Available from Armor Industrial – Your Trusted Source for Predictive Maintenance Solutions

The ADASH Lubri 4910 is a powerful handheld device that combines precise lubrication control with real-time vibration mo

Monitor vibration and optimize greasing with the ADASH Lubri 4910 from Armor Industrial—improve bearing health and extend machine life.

nitoring. Designed to help technicians optimize greasing while tracking bearing and machine health, the Lubri 4910 improves performance and extends equipment life.

Key Features

Precision Lubrication Guidance

Attach the Lubri 4910 directly to a bearing housing. As you add grease, the device monitors vibration in real time. When the vibration levels stop decreasing, the bearing has received the optimal amount of grease—no more, no less.

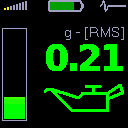

Dual Vibration Measurement

-

Bearing Condition: Measures acceleration (g) to assess the health of the bearing.

-

Machine Condition: Measures velocity (mm/s or ips) to evaluate the entire machine’s performance.

Data Storage and Trend Monitoring

Collect and store vibration readings each time you use the Lubri 4910. Later, import the data into Adash’s free DDS software to analyze trends and track machine condition over time.

Easy to Use and Non-Invasive

The Lubri 4910 requires no disassembly or complex setup. Simply attach it to the bearing housing, pump grease, and monitor the change in vibration values on the screen.

Using the Lubri 4910 regularly helps eliminate over-greasing, a common cause of premature bearing failure. At the same time, it provides insight into potential mechanical issues before they result in downtime.

Please select from the options above to integrate the ADASH Lubri 4910 into your maintenance routine and protect your most valuable assets.