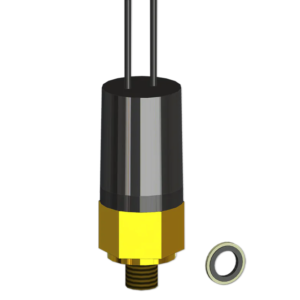

Introducing the Oil Brush with Nylon Bristles and 1/8” NPTM Connection (Part #803-11)—a precision-engineered lubrication accessory designed for efficient and controlled application of oils and lubricants in industrial settings.

Key Features:

-

Durable Nylon Bristles: This oil brush features high-quality nylon bristles that provide excellent resistance to wear and chemicals, ensuring longevity and consistent performance.

-

Standard 1/8” NPTM Connection: Equipped with a 1/8-inch NPT male thread, this oil brush seamlessly integrates with standard lubrication systems. This allows for quick and secure attachment.

-

Compact Dimensions: Measuring 2.25 inches in length, 1.75 inches in width, and 3/8 inch in thickness. The brush is designed to access tight spaces and apply lubricant precisely where needed.

Applications:

This oil brush with nylon bristles is ideal for use in various industrial applications, including:

-

Chain Lubrication: Ensures even distribution of lubricant on chains, reducing wear and extending service life.

-

Gear Maintenance: Facilitates the application of lubricants to gears, promoting smooth operation and minimizing friction.

-

Conveyor Systems: Applies lubricant to conveyor components, aiding in the reduction of operational noise and wear.

Benefits:

-

Efficient Lubrication: The brush design allows for controlled and targeted application. This allows users to minimize waste and ensuring that lubricant is applied exactly where needed.

-

Easy Integration: The standard NPTM connection ensures compatibility with a wide range of lubrication systems, simplifying installation and replacement.

-

Enhanced Equipment Longevity: Regular and precise lubrication helps in reducing equipment downtime and maintenance costs by preventing premature wear.

For optimal performance, pair this oil brush with compatible lubrication systems and ensure regular maintenance checks to maintain its efficacy.

Note: Always verify compatibility with your specific equipment and lubrication system requirements before installation.